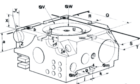

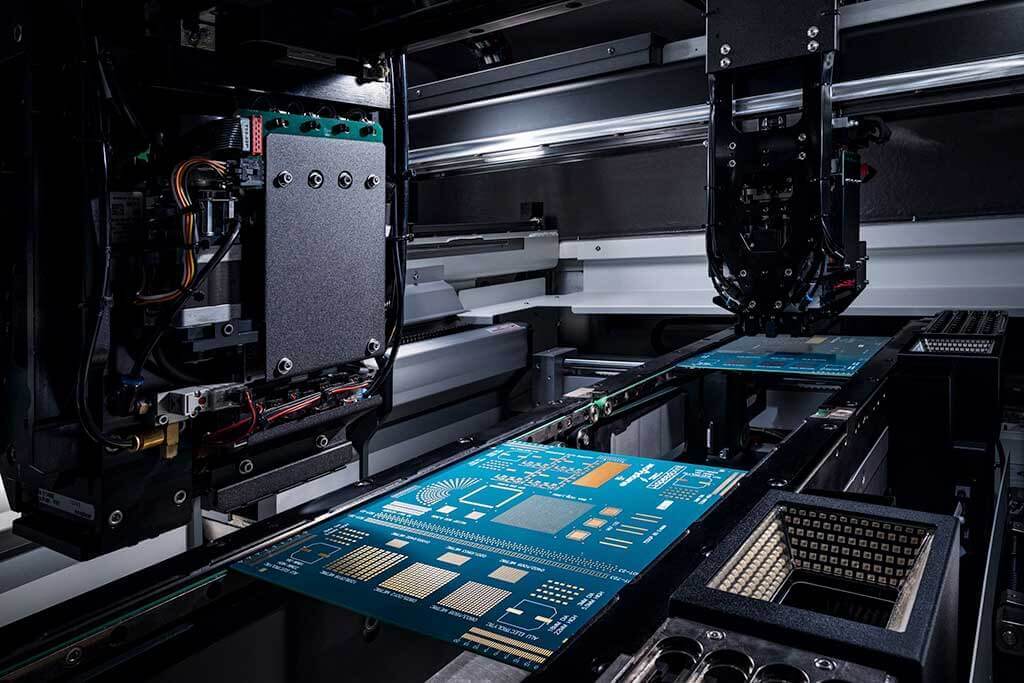

With placement speeds up to 50,000cph, theii-A2 levels up the line by providing a resource that optimizes the placement process while maximizing the performance and throughput of Europlacer machines downstream. It has a feeder capacity of 164 x 8mm positions and handles components from 01005 profiles to 13mm x 13mm x 7mm dimensions – all in a compact module footprint. The high speed SMT modular placement system ii-A2 is designed to deliver fast, fully intelligent and highly integrated productivity. ii-A2 is fully compatible with all relevant atom platform innovations and options, and with all Europlacer intelligent feeder technologies. It features Europlacer’s patented intelligent conveyor with board stops under full software control. Despite the compact module format, ii-A2 can handle boards up to one meter (39 inches) in length.

Features / Benefits

- 2 x Pulsar pipette heads with 8 placement smart nozzles

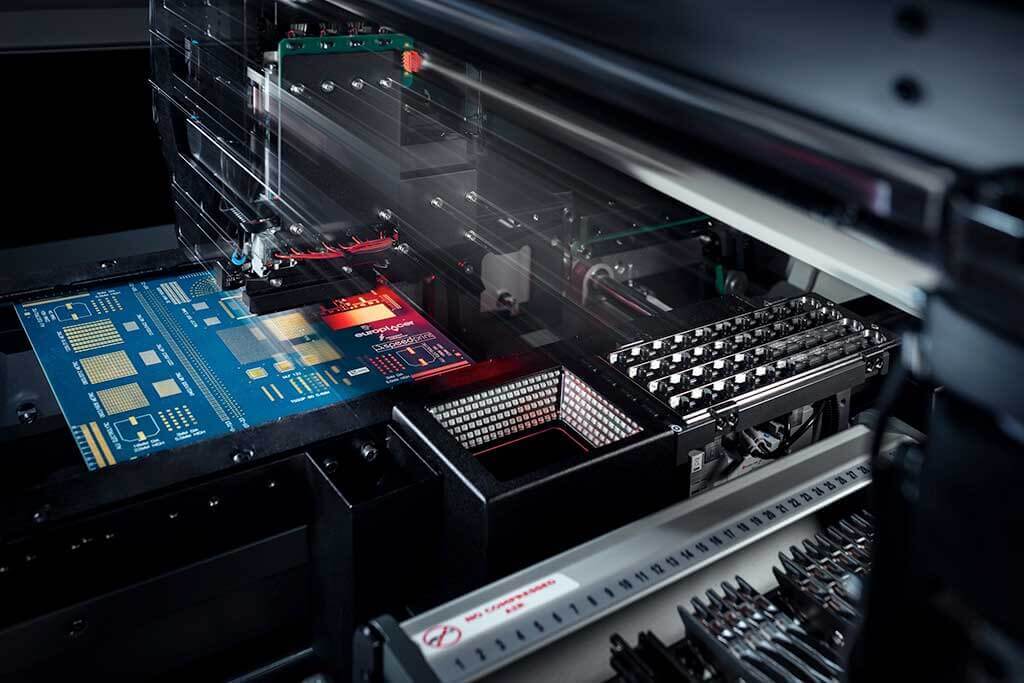

- Electrical component testing with independently verifiable calibration (UKAS / NIST / PTB…etc)

- Glue dispenser, Glue/paste Dispenser with Auger valve

- Every nozzle position can place all and any component types, for real line balancing and no limitations

- Odd form & smart nozzle banks

Technical Data

- PCB sizes – up to 1088mm x 460mm / 510 mm (without camera+nozzles at rear) / 715 mm (without feeder at rear)

- 164 x 8mm

- 01005 to 13 x 13mm components

- Component height – 7mm

Options / Accessories

Up to 2x ‘fly over’ high resolution digital camera at rear, Up to 2x additionnal 40 positions nozzle magazines at rear, Motorization of conveyor width adjustment, HeavyPCB kit for conveyor (10 kgs), Wide pcb kit 715mm (with no feeder at the rear), Rear operating station, Keyboard, mouse, support, Offline preparation, Stock Management, Full Traceability, PROMON Software, Barcode feeders, Bulk feeders, Ball feeders for BGAs, Flux feeder & PoP processing