SMT placement

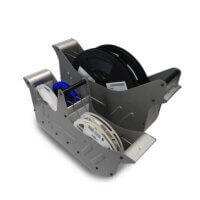

On most of pick and place machines, the heads can only place a specific range of components.It certainly just makes life complicated. As a result you can’t effectively balance that single machine, let alone a complete line. That’s why the SMT placement machine iineo+ has genuine line balancing capabilities. All heads and all nozzle positions capable of placing the full range of components. Above all, you don’t have to compromise on feeder positions or throughput speed, production can run as efficiently as is possible. Firstly iineo+ is fitted with linear motors and digital cameras. In addition, it utilises Europlacer’s unique and proven core features such as Integrated IntelligenceTM , intelligent feeders, smart nozzles and 3DPS. 3DPS provides guaranteed closed loop control of pick and placement forces for all components. Importantly, iineo+ is able to produce very large boards, as it is capable of being configured to manage 1610mm x 600mm size substrates. The SMT placement pick and place iineo+ I features a single rotary head on the X/Y gantry and contains 8 or 12 ‘Smart’ nozzles, with a maximum placement rate of 15,390 cph (IPC: 12,550 cph)

As you might expect from Europlacer, the SMT placement equipment iineo+ is a single elegant structure capable of almost unlimited configurations. The capability that comes as standard within the machine is however the most important aspect of this platform:

SMT placement

On most of pick and place machines, the heads can only place a specific range of components.It certainly just makes life complicated. As a result you can’t effectively balance that single machine, let alone a complete line. That’s why the SMT placement machine iineo+ has genuine line balancing capabilities. All heads and all nozzle positions capable of placing the full range of components. Above all, you don’t have to compromise on feeder positions or throughput speed, production can run as efficiently as is possible. Firstly iineo+ is fitted with linear motors and digital cameras. In addition, it utilises Europlacer’s unique and proven core features such as Integrated IntelligenceTM , intelligent feeders, smart nozzles and 3DPS. 3DPS provides guaranteed closed loop control of pick and placement forces for all components. Importantly, iineo+ is able to produce very large boards, as it is capable of being configured to manage 1610mm x 600mm size substrates. The SMT placement pick and place iineo+ I features a single rotary head on the X/Y gantry and contains 8 or 12 ‘Smart’ nozzles, with a maximum placement rate of 15,390 cph (IPC: 12,550 cph)

Features / Benefits

- One rotary turret head with 8 or 12 placement nozzles

- Up to 10 internal Jedec trays

- Component testing capability – with independently verifiable calibration (UKAS / NIST / PTB… etc.)

- Dispensing – archemedes or air/time for glue or solder paste

- Every nozzle position can place all and any component types, for real line balancing and no limitations

- Odd form & smart nozzle banks

Technical Data

- PCB sizes from 60mm x 60mm up to 1610mm x 460mm

- 264 x 8mm feeders

- 01005 to 99 x 99mm components

- Component weight & height – 300g and 34mm