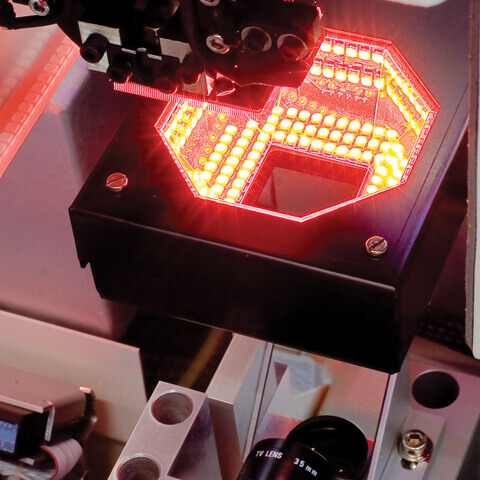

A powerful vision system is a key feature in any pick & place machine, and there are no short cuts. Europlacer developed its own vision algorithms to analyse QFPs back in the 1980s.This high-resolution camera is used for inspection of ultra fine pitch components, µBGA, and flip chip devices. It’s also used for components larger than the 50mm x 50mm specification of the “on the fly” camera, to give accurate machine vision up to 99mm x 99mm.It can acquire images in single field of view (SFOV) or multiple field of view (MFOV) modes. By locating it between the feeder zones on iineo, it does not reduce the maximum feeder count.

Features / Benefits

- Accurate machine vision up to 99mm x 99mm

- Single field of view (SFOV)

- Multiple field of view (MFOV)