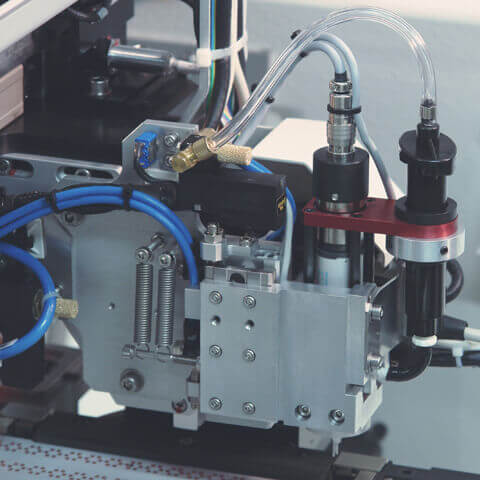

Mounted directly to the placement head and therefore utilising the positional accuracy and control, the dispenser provides consistent dots of glue or solder directly to the substrate prior to component placement.

Fully programmable, different dot sizes can be applied depending on package library parameters to increase the level of flexibility within the placement platform.

Adhesive dots are generally used to hold certain passive components onto the PCB during the wave soldering process.

With pin-in-paste technology, through-hole (PTH) component placement can follow the SMT component placement process, with both being reflowed together in the oven. Using our solder paste dispenser, plated-through component holes are filled before the insertion of the components. This eliminates the wave soldering process altogether to dramatically improve line throughput and efficiency.

Features / Benefits

Two dispensers are available on ii-Ax (atom) and iineo+ :

- air / time system – providing an economic dispensing system

- archimedean screw – the ultimate in control and performance