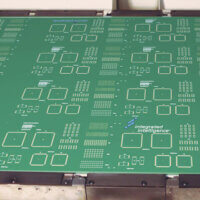

The EP1220 long board screen printer handles boards up to 48″ (1220mm) long and 20″ (508mm) wide, ideal for LED lighting applications.

The screen printer has an accuracy of 12.5µm at 6-sigma and uses four fiducials to optimise alignment across the large board area – a factor that becomes increasingly critical with long PCBs.

The machine also features in-built Solder Paste Inspection (SPI) technology for added process reassurance.

Features / Benefits

- Cycle times of 14 seconds

- Board length up to 48″

- Closed loop squeegee pressure control

- Inventive X-axis under stencil cleaning: wet/dry/vacuum

- 2-minute product changeover time

- 5-minute new product set up time

- Top clamping standard. Side clamping (with vacuum) optional

- 2D SPI built in

- Magnetic tooling support pins (laser-guided) as standard

- Fully automatic tooling support option

Inspection

SPI technology is built in to the EP1220 machines, giving on-board 2D inspection capability for paste presence and bridge detection.

Durability – Quality Assurance

Our screen printers are refined, robust, design-optimised products built to last.

Be assured that EP1220 screen printers will perform identically in a decade as they do when new.

Technical Data

- +/-12.5µm accuracy @ 6-sigma

Stencil Cleaning

The long board printer deploys an inventive under-stencil cleaning system that operates in the X-axis to minimise the usage of cleaning consumables.

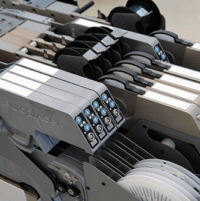

Automation

Advanced automation is at the very centre of our long board screen printer platforms.

The EP1220 features laser-guided manual support pin positioning as standard, and fully automatic tooling pin placement as an option.

Options / Accessories

A range of production and process options are available with the EP1220long board screen printer, allowing you to implement additional efficiencies and controls within your printing process.