Features:

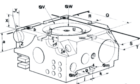

Machine Base:

Heavily ribbed cast iron structure with integrated dove tailed slideway for the workhead and steady rest.

The machine base houses an industrial type flood pump for delivering coolant to the grinding site and a baffled drawer type coolant reservoir which can be drawn out for ease of cleaning.

The machine base houses also the control panel for the motors.

Grinding Spindle:

The permanently sealed and lubricated grinding spindle slides on a swivel plate which is provided with an integrated dove tailed slideway.

The swivel plate is set to the desired valve angle by means of a wide spaced scale.

Workhead and Steady Rest:

Monobloc work spindle with permanently sealed and lubricated work spindle bearings. Work spindle fitted with collet chuck for use of high precision collets.

A micrometer infeed unit is combined with the workhead to feed the face of the valve clamped in the collet to the grinding wheel.

An unique selfcentering steady rest is provided for additional support of long stem valves.

Both the workhead and the stready rest are adjustable along the slideway on the machine base to clamp the valve on that part of the valve stem which normally travels in the valve guide.

Dressing Attachment:

The dressing attachment is permanently mounted on the worktable for rapid wheel dressing.

Electrical System:

Individual grinding spindle motor, work spindle motor and coolant pump motor all controlled by switsches grouped in front of the machine base for ease of operation.

Specifactions:

| Capacity: | |

| Valve stem diam. | 5 – 32,5mm |

| Max. valve head diam. | 200mm |

| Valve seat angle | 18°- 47° |

| Grinding spindle: | |

| Grinding wheel diam. | 175mm |

| Speed at 50Hz | 2790rpm |

| Work spindle | |

| Speed at 50Hz | 25rpm |

| Coolant system: | |

| Coolant capacity | 5 liters |

| Power requirement: | |

| Supply voltage | 400V±10% |

| (3ph 50/60Hz) or | 230V±10% |

| Power input | 0,6kW |

| Dimensions: | |

| Length | 800mm |

| Width | 550mm |

| Height | 500mm |

| Weight: | |

| Net weight | 115kg |