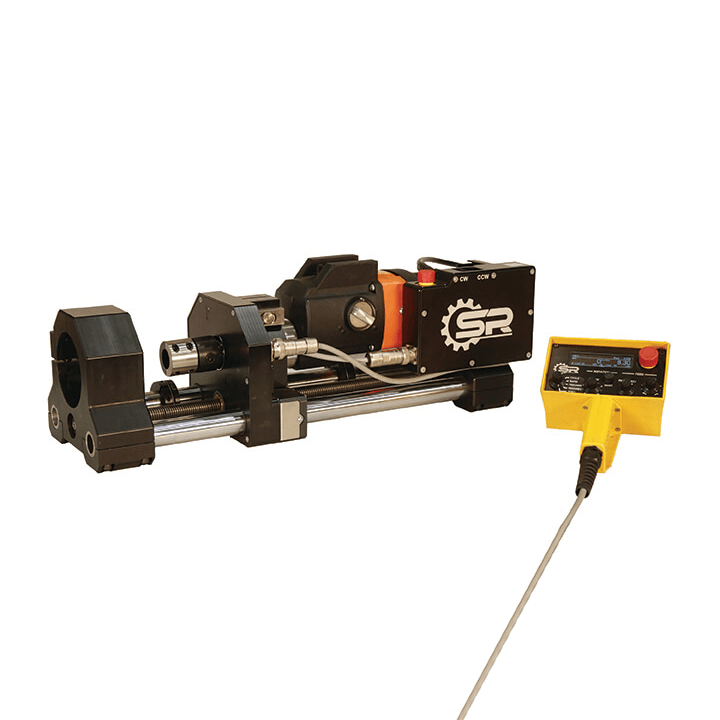

A new bar coupler provides easier set-up while reducing vibration, and larger guide bars double its rigidity. The 4-14 S2 is designed for power and precision with its all-new digital hand unit with easy-to-read display. Its advanced features include precise RPM and feed control, a digital readout (DRO) for accurate positioning, Cycle Mode for automating cuts, and load monitoring that allows you to push the machine to its limit.

Advantages

- Lighter, 2x stiffer and has a smaller footprint than its predecessor

- All-new easy-to-read digital display showing feed current, feed rate, and RPM

- Accurate position control with DRO

- Automated cutting with Cycle Mode

- Load monitoring of feed and rotation with automatic shut-off

- Cutting tool travel 14.5 in (368 mm)

- Feed per minute ranging from 0 – 6.5 in per minute (165 mm per minute)

- Feed per rev starting at .1 – 20.5 thou per rev (.0025 – .521 mm per rev)

- Rapid traverse at 8.3 in per minute (211 mm per minute)

- Super lightweight base machine weights 51 lbs (23.1 kg); and the pendant at 3 lbs (1.36 kg)

- Powerful four variable speed reversible bar drive 3hp (2200W) motor weighing in at 26.5 lbs (12.02 kg)

- Available in 110 V & 230V systems

- Includes wide range of bore diameters from 1.5 to 16 in (38.1 to 406.4 mm)

- Bar drive torque at 203 ft-lbs of torque (275 Nm)