Standard Equipment

- Siemens 828D ShopTurn Control.

- Hydraulic 200mm 3 Jaw Chuck.

- Sauter ‘German’ VDI Turret.

- Parts Catcher.

- Through Tool and Flood Coolant.

- Remote Electronic Handwheel.

- USB Port.

- Networking.

- Renishaw Automatic Tool Setting Arm.

- Swarf Conveyor & Bin.

- Programmable Hydraulic Tailstock.

Optional Equipment

- Collet Chuck.

- Bar Puller.

- Barfeed Units.

- Offline Programming.

- Contour Handwheel.

- Gear Hobbing.

- Polygon Turning.

Advanced Swarf Management System.

The CT 65 LTY Turning Centre for quick one hit mill/turn production.

The smallest Y axis turning centre in the XYZ range offers great production capabilities from a very small footprint.

The CT 65 LTY is a perfectly sized, yet solidly built, versatile turning centre that makes the most of the smallest of shopfloor spaces. Standard equipment, not normally found on machines of this type, include hydraulic chuck, 12-station VDI turret, Renishaw tool setting, swarf conveyor and tailstock. The latest in conversational control technology from Siemens the 828D ShopTurn, makes the machine ideal for experienced and novice CNC users alike.

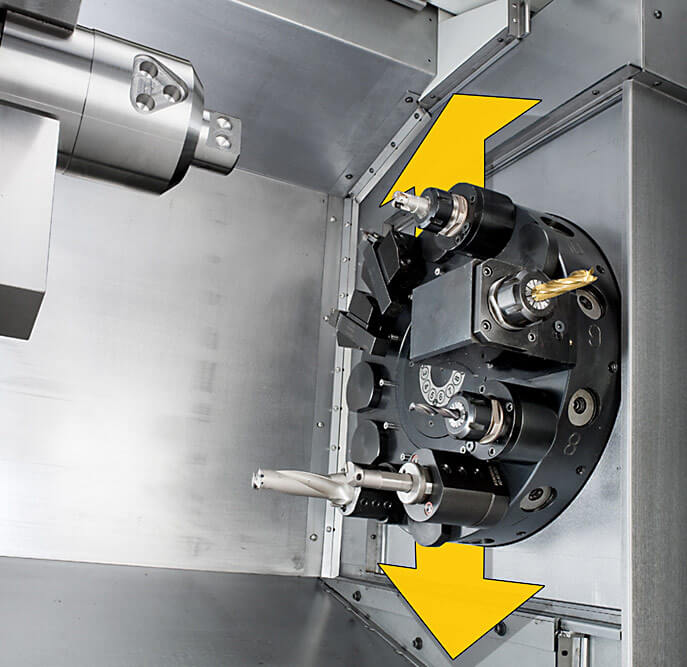

The addition of the Y axis and live tooling means that productivity can be enhanced as many components that require turning and milling can come off the CT 65 LTY finished.

The ‘Y’ axis of the XYZ COMPACT TURN 65 LTY can travel 35mm above and below centreline (70mm total travel), making easy work of most components that would normally require milling and turning operations.

| XYZ CT 65 LTY live tooling C axis | |

| No. of stations | 12, all live |

| Max rpm | 4500 rpm |

| Power 40% rating | 4 kW |

| ‘C’ axis resolution | 0.001º |

| Conforming to ISO 13041 | |

| Positional accuracy | +/- 5 microns |

| Repeatability | +/- 2 microns |

| Cutting accuracy over 100mm | 10 microns |

| Geometric accuracy over 100mm | 10 microns |