Standard Equipment

- Siemens 828 ShopTurn/ShopMill

Touchscreen Control. - 200mm Hydraulic Chuck on Main Spindle.

- 150mm Chuck on Sub Spindle.

- Sauter “German” Turret 12 Station VDI30.

- Y Axis.

- Live Tooling.

- Parts Catcher.

- Swarf Conveyor and Bin.

- Renishaw Automatic Toolsetting Probes.

- C Axis for Complex Contour with Brake.

- 30° One Piece Slant Bed.

Optional Equipment

- Bar Feed.

- Collet Chuck.

- Contour Handwheel.

- Advanced Swarf Management.

- Offline Programming.

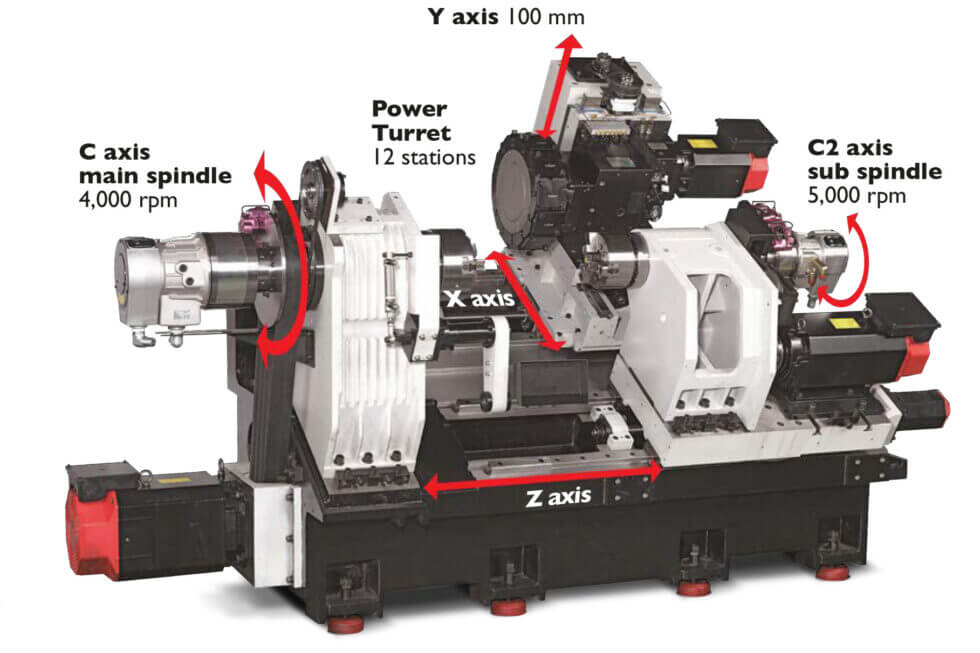

The brand new XYZ Twin/sub spindle 65 Turning Centre

This new machine in the XYZ range is perfect for those larger production runs, where the whole job is best done in one hit.

The twin / sub spindle turning centre with live tooling and Y axis gives you the ability to machine both ends of a component reducing the frequency of loading and unloading. This reduces idle time and improves productivity, milling and turning can be done in one set up.

The 30°one-piece slant bed provides a rigid base.

Linear ways ensure faster travel and precision.

| Conforming to ISO 13041 | |

| Positional accuracy | +/- 5 microns |

| Repeatability | +/- 2 microns |

| Cutting accuracy over 100mm | 10 microns |

| Geometric accuracy over 100mm | 10 microns |