Standard Equipment

- Siemens 828D ShopTurn Control.

- Hydraulic 315mm 3 Jaw Chuck.

- Sauter ‘German’ VDI Turret.

- Automatic Tool Setting Arm.

- Swarf Conveyor & Bin.

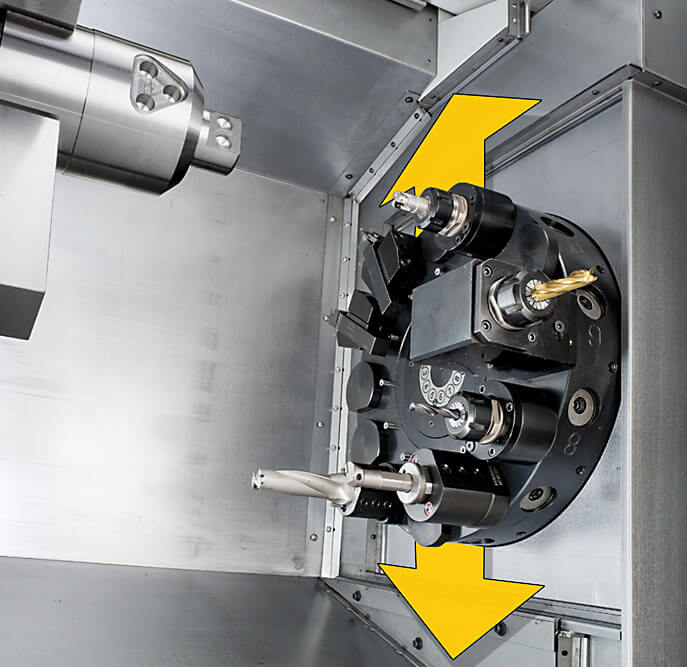

- VDI Turret.

- Full ‘C’ Axis.

- Live Tooling.

- 100mm Y axis.

- Programmable Hydraulic Tailstock.

- Through Tool and Flood Coolant.

- Remote Electronic Handwheel.

- USB Port.

- Networking.

Optional Equipment

- Parts Catcher.

- Collet Chuck.

- Bar Puller.

- Barfeed Units.

- Offline Programming.

- Contour Handwheel.

- Gear Hobbing.

- Polygon Turning.

- Advanced Swarf Management System.

The TC 320 LTY packs a powerful productivity punch.

The XYZ TC 320 LTY is the largest y-axis turning centre in the XYZ range and provides users with exceptional capacity from a solid cast machine base.

The addition of the 100 mm Y axis (+/-50 mm) adds a degree of versatility to the machine that allows many parts to be machined complete, increasing productivity significantly. Added to this is the extensive list of standard equipment that makes the XYZ TC 320 LTY a highly competitive turning

centre package. This list includes hydraulic chuck, 12-station (all live) VDI turret, Renishaw tool setting, swarf conveyor and the market leading Siemens 828D ShopTurn conversational control.

The ‘Y’ axis of the XYZ TC 320 LTY can travel 50mm above and below centreline (100mm total travel), making easy work of most components that would normally require milling and turning operations.

| XYZ TC 320 LTY live tooling C axis | |

| No. of stations | 12, all live |

| Max rpm | 4500 rpm |

| Power 40% rating | 6 kW |

| ‘C’ axis resolution | 0.001º |

| Conforming to ISO 13041 | |

| Positional accuracy | +/- 5 microns |

| Repeatability | +/- 2 microns |

| Cutting accuracy over 100mm | 10 microns |

| Geometric accuracy over 100mm | 10 microns |