| STANDARD MACHINE SPECIFICATION | LTC10T.10 | LTC10T.12 | ||

| CAPACITY | Height of centers | mm | 400 | |

| Swing over bed | mm | 800 | ||

| Swing over cross slide | mm | 560 | ||

| Width of bed | mm | 560 | ||

| Distance between centers | mm | 1500; 2000; 3000; 4000; 5000; 6000 | ||

| SPINDLE | Spindle nose DIN 55027 | No | A 20 / A2 20 | |

| Front bearing diameter | mm | 380 | ||

| Spindle bore | mm | 260 | 315 | |

| HEAD STOCK | Number of spindle speeds | 4 | ||

| I – Range | rpm | 8 – 40 | ||

| II – Range | rpm | 16 – 80 | ||

| III – Range | rpm | 40 – 200 | ||

| IV – Range | rpm | 80 – 400 | ||

| TRAVELS AND FEEDS | Longitudinal feed (Z-axis) | m/min | 8 (max) | |

| Lateral feed (X-axis) | m/min | 8 (max) | ||

| Rapid traverse (Z and X-axis) | m/min | 8 (max) | ||

| Cross slide maximum travel | mm | 390 | ||

| BALL SCREW | Z-axis | mm | 50 х 10 | |

| X-axis | mm | 32 х 5 | ||

| TAIL STOCK | Quill diameter | mm | 105 | |

| Quill travel | mm | 225 | ||

| Quill taper | Morse | 6 | ||

| DRIVES | Main drive power | kW | 18,5kW (AT180M4) | |

| Z-axis servo drive power | kW/N.m | 18 N.m (3,77kW) (1FK7100) | ||

| X-axis servo drive power | kW/N.m | 11 N.m (2,29kW) (1FK7063) | ||

| Spindle maximum torque | N.m | 3500 | ||

| Z-axis tow strength | daN | 1250 | ||

| X-axis tow strength | daN | 1050 | ||

| TOOL HOLER | Quick change type | MC | ||

| CNC SYSTEM | Siemens | |||

| WEIGHT | For DBC 3000 mm | kg | 6100 | |

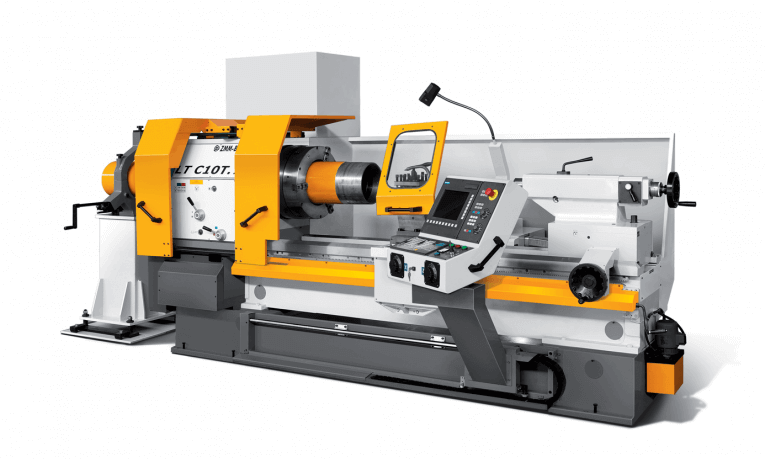

LTC10T.10/LTC10T.12

Computer numerical control lathes are modern metal cutting machines, full of technological opportunities. They are suitable for processing parts with highly complex surfaces where the requirements for dimensional accuracy do not tolerate any deviation. These lathes are used in a variety of serial productions in the field of mechanical and automobile engineering, and many others, of course.