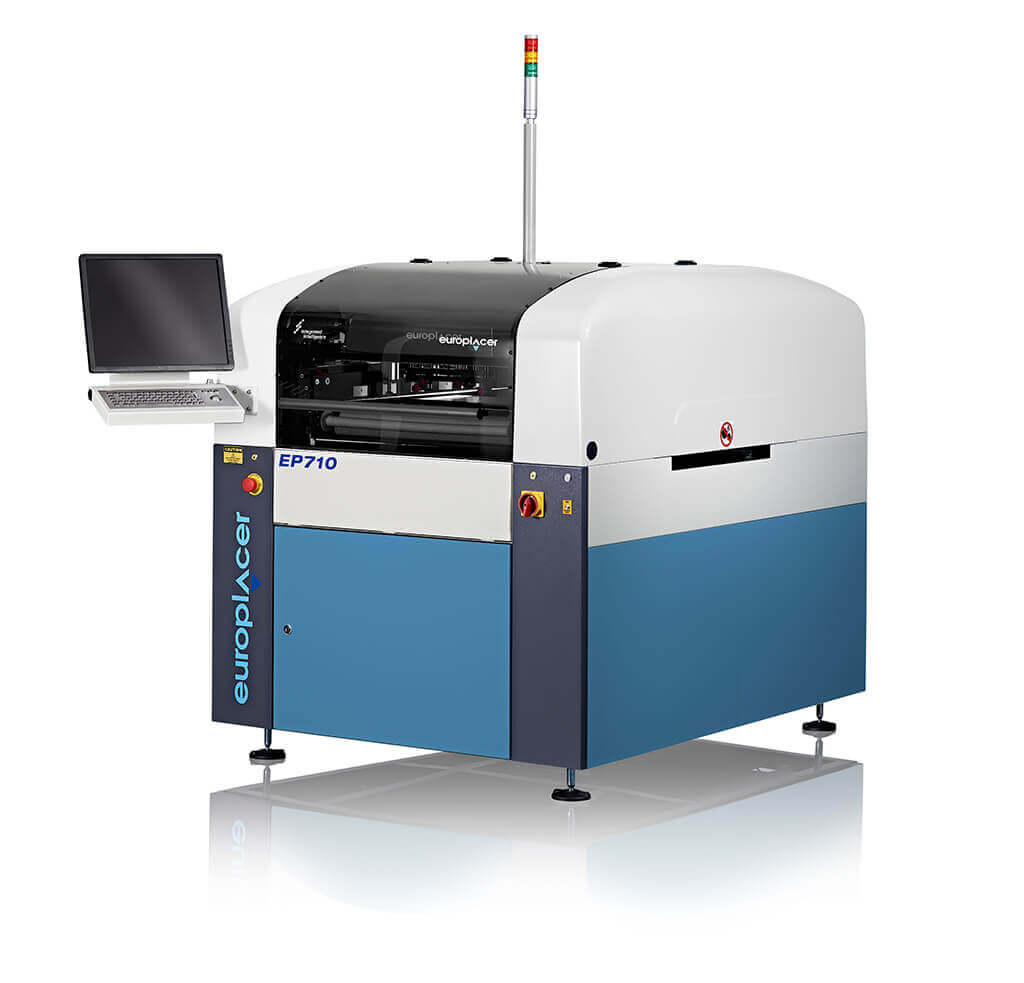

Designed with ease of use, high-end performance and low cost of ownership in mind, the high flexibility screen printer utilises the most advanced drive control technology available, including 1 micron resolution linear encoders on all axes. A suite of intuitive software enables total control of the printing process.

The printers are fully equipped, as standard, with many features such as automatic rail width adjust, auto stencil loading, a fully programmable Under Stencil Cleaner and even automatic stencil paste inspection.

In fact, everything you need to complete the SMT screen print process without exception or compromise.

The PCB transport system includes a fully programmable board stop and employs pneumatically controlled foil PCB clamping.

The system is SMEMA compatible to ease integration with fully automated SMT production lines.

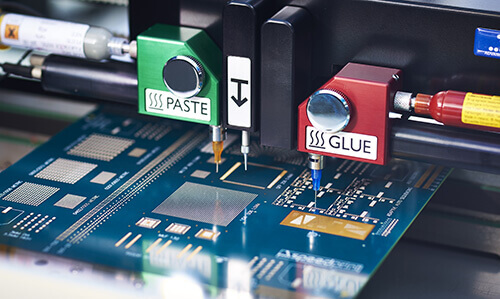

Vision System – Unrivalled accuracy

Exceptional repeatability and print accuracy stem from meticulous alignment.

Our patented Dual Roving camera (DRc) technology precisely aligns the board and stencil, and checks for solder paste presence on the stencil before printing.

DRc innovations include SmartCal, a zero-cost straightforward calibration facility that lets operators validate the process in 30 seconds or less.

SmartCal helps to maximise and maintain your process window, delivering optimum performance for the operational life of the printer.

Features / Benefits

- Fully programmable board stop

- Highly efficient vacuum-assisted under stencil cleaning:

fully programmable, wet or dry, with or without vacuum - Auto stencil load and eject to streamline product changeover

- Closed loop dual squeegee control for print process optimisation

- Fully programmable print parameters

- Defect prevention with programmable Optical Paste Bead Management

Verifies solder paste presence on the stencil

Alerts to insufficient volume

Safeguards quality - SmartCal cost-free instant process calibration

- SPI communication

- Maximum positional accuracy with 1-micron resolution linear encoders on all axes

Automation

Features include closed-loop print head control, bi-directional board clamping and laser-guided tooling to ensure fast, efficient and accurate tooling support set up.

Technical Data

- Cycle time 11.5 seconds standard, 8 seconds option

- Print speed 5mm/sec to 250mm/sec

- Alignment repeatability to 12.5µm @ 6-Sigma 2Cpk

- Full process repeatability to 20µm @ 6-Sigma 2Cpk

Options / Accessories

A range of production and process options are available across the EP700 screen printer series, allowing you to implement additional efficiencies and controls within your printing process.